Understanding the Key Differences: Vendor vs Supplier

In 2024, over 99% of Global 2000 companies were directly linked to at least one third-party vendor involved in a documented breach, and for 20% of them, that meant managing thousands of external products and services.

That stark figure shows why understanding vendor vs supplier isn’t just semantics, it could determine whether a disruption halts production or just delays a shipment. As outsourcing and vendor ecosystems grow, so does the need for clarity in procurement, risk planning, and partner evaluation.

This article dives into the practical differences between vendors and suppliers, who fits each role, how to decide which your business needs, and what that means for reliability, security, and scalability.

Before we dive in:

Vendors offer finished goods or services; suppliers provide raw materials or key inputs.

The right choice depends on your industry, operational model, and procurement priorities.

Reliable partner evaluation reduces delays, inventory issues, and downstream risk.

Visibility into security, quality, and performance is essential for both partner types.

Auditive helps teams evaluate and monitor external partners with consistent, automated workflows.

Who Is a Vendor?

A vendor is an individual or business that sells finished or semi-finished products directly to other businesses or end consumers. Some vendors manufacture the products themselves, while others source, re-package, or re-label goods before selling them under their own brand.

Core Responsibilities of a Vendor (Straightforward & Accurate)

Maintain Product and Service Quality

Vendors sell finished or packaged goods, so they are accountable for consistent quality, whether they manufacture the product or resell it.

Deliver on Time

In B2B environments, late vendor deliveries disrupt production and supply schedules. In B2C, they directly affect customer experience. Meeting agreed delivery timelines is a foundational vendor responsibility.

Manage Inventory Efficiently

To avoid stockouts, delays, or missed commitments, vendors must track, maintain, and forecast inventory levels accurately.

Provide Clear Customer Communication

Vendors share order updates, logistics information, and other delivery-related details to support transparency and help businesses manage risks tied to delays or changes.

Handle Post-Sales Support

Depending on the agreement, a vendor may process returns, refunds, replacements, or product-related queries, either on behalf of manufacturers or as part of their own service commitment.

Maintain Accurate Documentation

Vendors keep detailed transaction records, contracts, and supporting documents. These records help them meet contractual obligations and avoid legal or operational disputes.

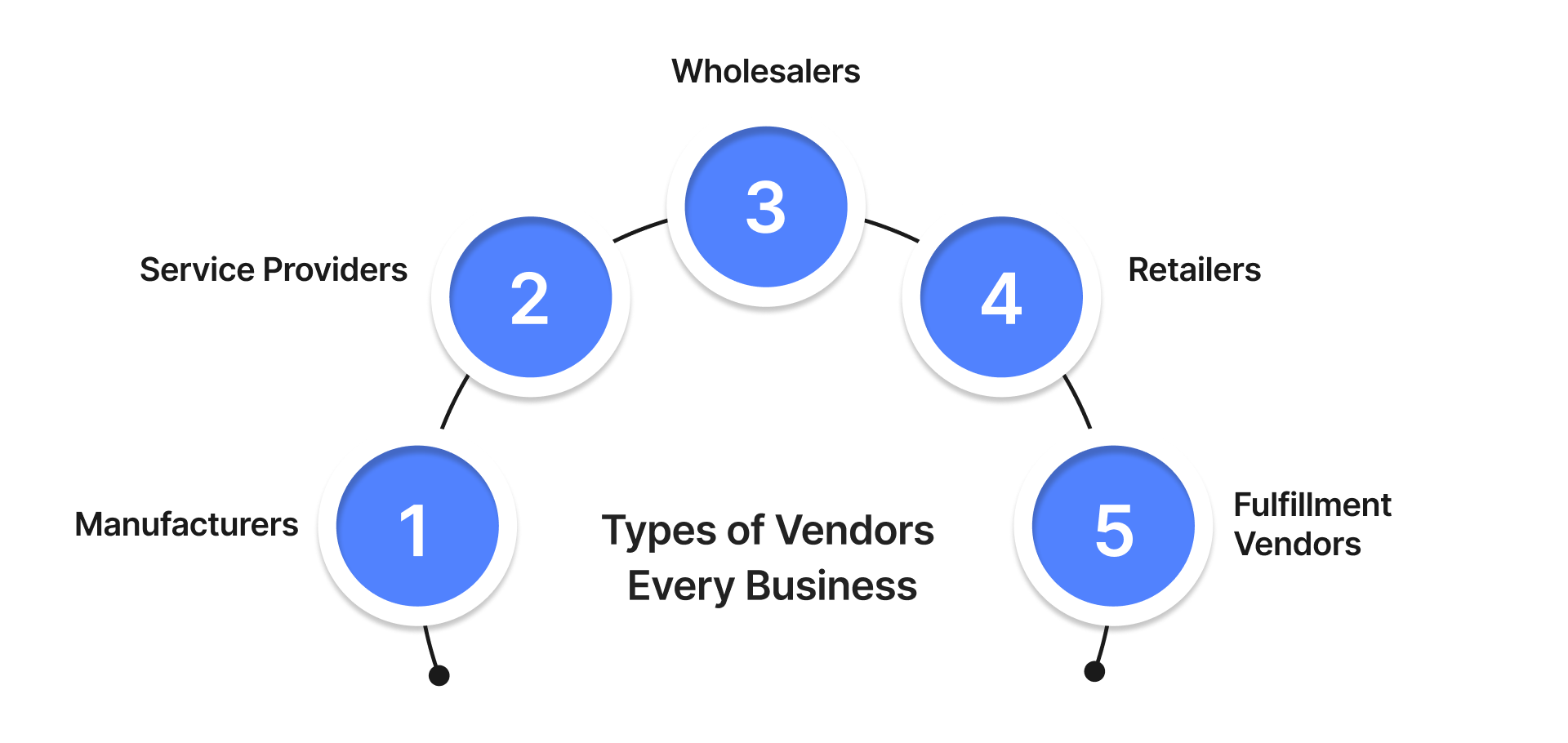

Types of Vendors Every Business Should Understand

A quick breakdown to clarify the vendor vs supplier distinction and help you map the right relationships for your operations.

Understanding the core vendor categories makes it easier to evaluate capabilities, assess risk, and distinguish vendor vs supplier roles with precision. Here’s a concise, practical view based on what businesses actually rely on today:

1. Manufacturers

Vendors that operate production units and sell items they create or assemble. Their scope ranges from transforming raw materials into finished products to repackaging goods sourced in bulk.

When it matters: Long product cycles, cost efficiency, and consistent quality control.

2. Service Providers

These vendors deliver specialized services such as IT management, logistics, accounting, customer support, or digital marketing.

When it matters: Operational continuity, expert-led tasks, and reducing internal workload.

3. Wholesalers

Resellers who buy directly from manufacturers and sell in bulk to other businesses. They don’t produce goods but streamline distribution.

When it matters: Bulk procurement, predictable supply availability, and volume-based pricing.

4. Retailers

Consumer-facing vendors selling directly to end users across physical, digital, or hybrid storefronts.

When it matters: B2C operations, last-mile sales, and brand experience.

5. Fulfillment Vendors (Drop-Shippers)

These vendors manage inventory, order processing, and delivery for brands that outsource fulfillment. They often support B2C scaling without internal warehouse overhead.

When it matters: Rapid e-commerce launch, low-cost scalability, and outsourced logistics.

Who Is a Supplier? A Clear Breakdown in the Vendor vs Supplier Conversation

Suppliers are entities that source and deliver raw materials, semi-processed inputs, or critical machine components directly to manufacturers. Their operations are almost entirely B2B, and the scale is significantly larger than typical vendor transactions.

A single business can act as both, for example, a flour manufacturer supplying bulk quantities to bakeries (supplier) while selling packaged flour in retail stores (vendor).

Key Responsibilities of a Supplier (Straight and Practical)

Quality assurance

Suppliers are accountable for the quality of every batch they deliver. B2B buyers maintain strict acceptance standards, and any deviation can result in rejected shipments or contract loss.

On-time delivery

Because suppliers sit at the start of the production chain, delays can halt manufacturing altogether. Timeliness is usually a contractual requirement, not an optional courtesy.

Operational communication

Manufacturers depend on real-time updates on dispatch, transport, and delivery status. Suppliers must maintain consistent communication to prevent bottlenecks.

Competitive pricing

Success in B2B supply hinges on pricing that reflects volume, contract duration, and delivery terms, not just unit cost.

Inventory management

Suppliers must maintain buffer stock and monitor customer inventory levels to prevent production slowdowns caused by shortages or transportation disruptions.

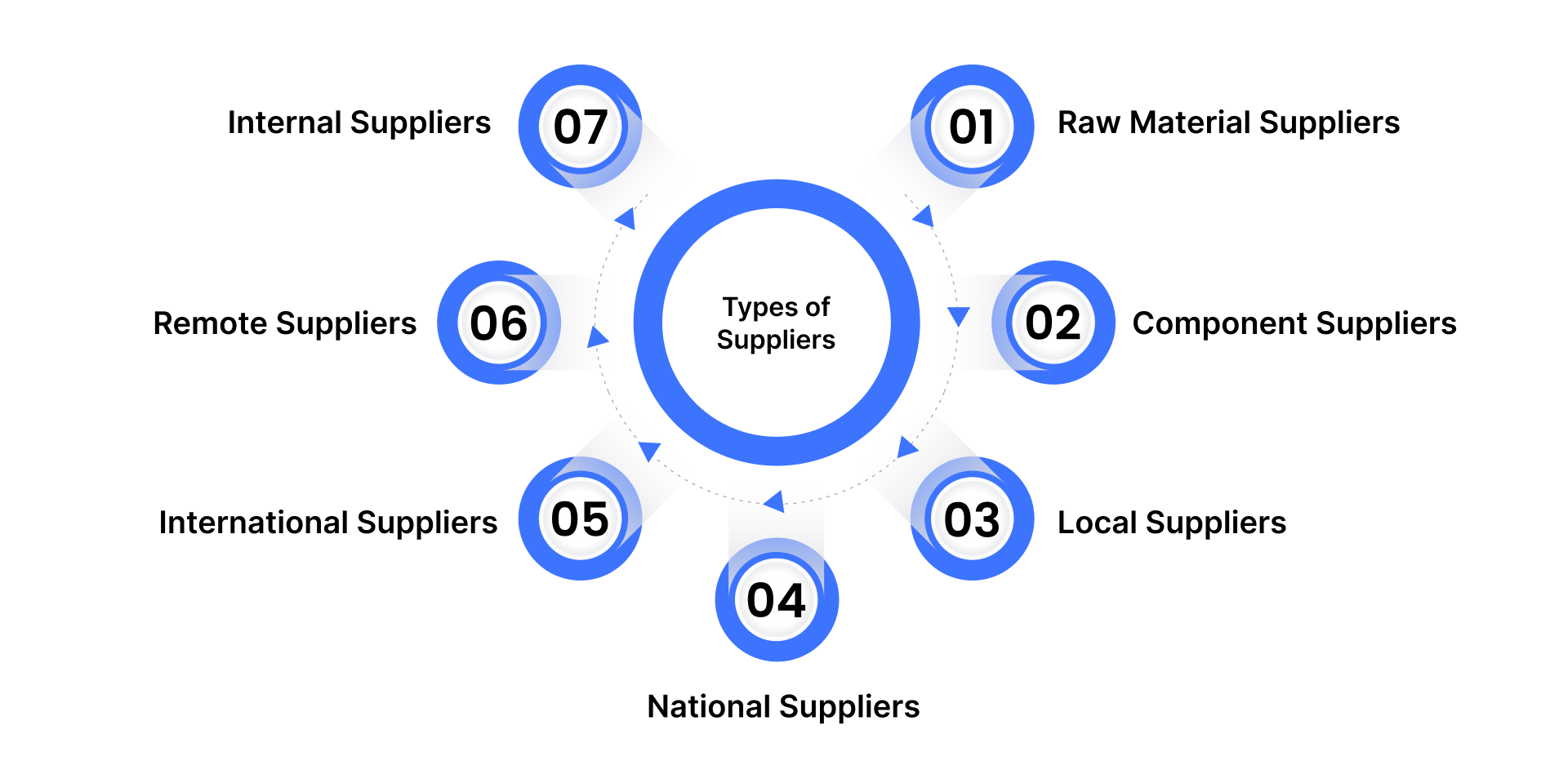

Types of Suppliers: The Categories That Shape Every Vendor vs Supplier Decision

Understanding supplier types helps clarify where they fit in the vendor vs supplier equation and how each impacts cost, reliability, and operational continuity.

1. Raw Material Suppliers

These suppliers provide the base inputs manufacturers need before production even begins.

Supply unprocessed or semi-processed materials

Common examples: metal ore, bulk chemicals, fabric rolls, grain, flour, vegetables

Critical for businesses with material-heavy production cycles

2. Component Suppliers

Suppliers that deliver pre-made parts required to build a final product.

Classified into non-critical, leverage, bottleneck, and strategic components

Example: semiconductor chips, one of the biggest bottleneck items during the COVID-19 period

Directly influence production capacity and lead times

3. Local Suppliers

Suppliers that operate within the same city or region as the buyer.

Offer faster delivery and simpler logistics

Useful for daily operational needs and quick replenishment

4. National Suppliers

Suppliers that serve multiple regions within a country.

May manufacture in one hub but distribute nationwide

Ideal for organizations with geographically distributed operations

5. International Suppliers

Global suppliers that source or manufacture from a primary hub but ship across countries.

Enable access to specialized materials or lower-cost production

Require strong logistics and cross-border coordination

6. Remote Suppliers

Similar to international suppliers but without any physical presence in the buyer’s region.

Operate primarily online

Suitable for standardized or catalog-based purchasing needs

7. Internal Suppliers

Subsidiary or sister companies within the same corporate group that supply materials or components.

Common in large enterprises with vertically integrated operations

Improves cost efficiency and supply predictability

A clear understanding of these categories helps teams differentiate vendor vs supplier roles more effectively, ensuring procurement decisions align with quality, cost, and operational needs.

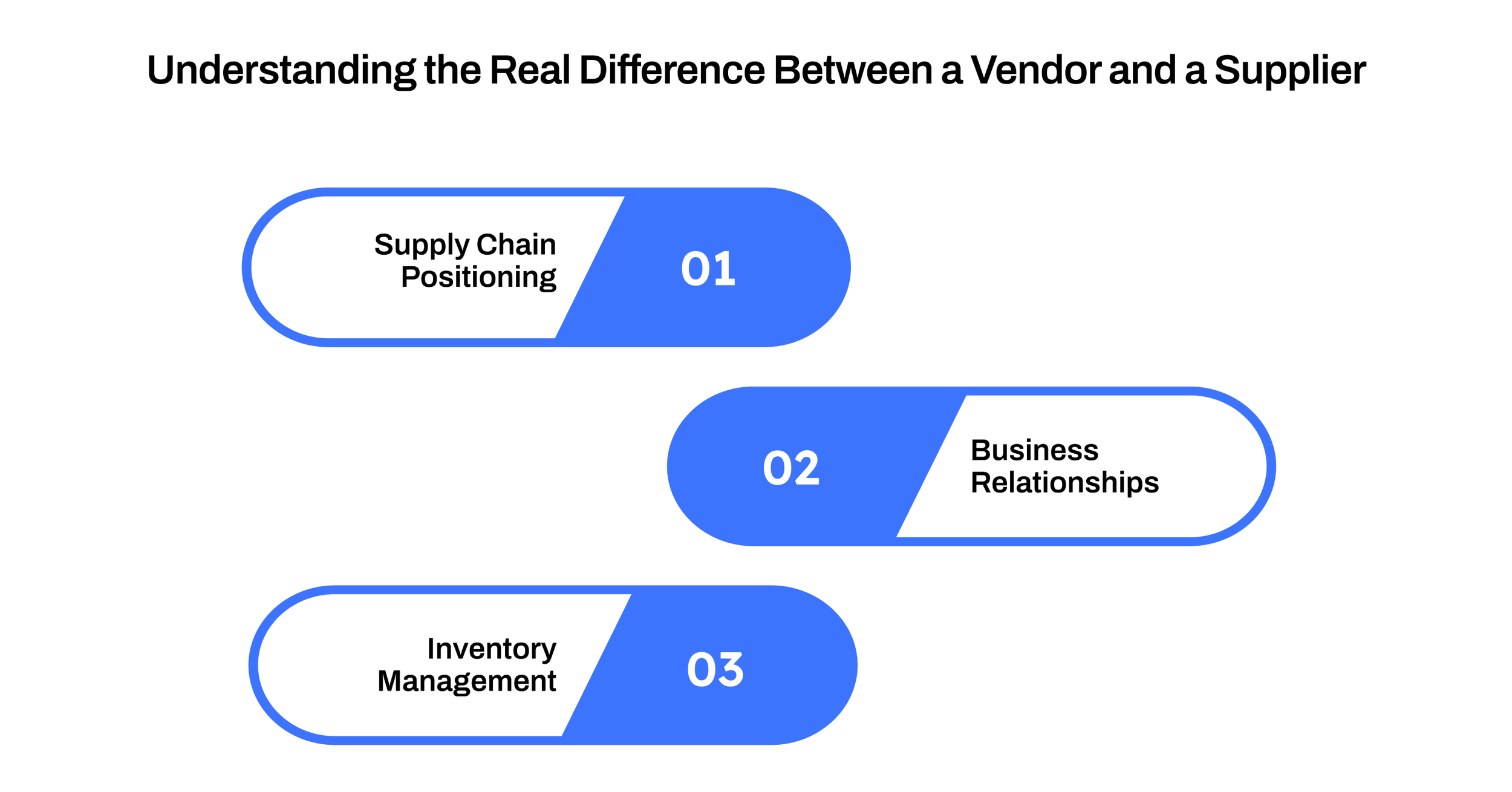

Understanding the Real Difference Between a Vendor and a Supplier

Many teams use vendor and supplier as if they mean the same thing, but they play completely different roles in how products move through a business. The keyword vendor vs supplier isn’t just a terminology debate, it directly affects sourcing decisions, cost control, contract terms, and how you structure your procurement strategy.

Vendors operate closest to the end user. Suppliers sit at the start of the production chain. Mixing them up leads to inefficient communication loops, mismatched expectations, and slower decision-making.

Here’s a precise breakdown of how each role functions.

1. Supply Chain Positioning

Supplier:

Provides raw materials, components, or inputs used in manufacturing.

Operates at the earliest stage of the supply chain.

Directly affects production timelines and cost structures.

Vendor:

Sells finished goods or services ready for consumption or resale.

Operates at the final stage of the supply chain.

Connects products to the market, retailers, distributors, or customers.

Why it matters:

Misclassifying a supplier as a vendor (or vice versa) leads to incorrect workflows, especially in procurement approvals, risk assessments, and lead-time planning.

2. Business Relationships

Supplier relationships center on:

Long-term contracts

High-volume consistency

Predictable delivery cycles

Quality of raw materials

These partnerships are usually stable, process-driven, and built around continuity.

Vendor relationships focus on:

Market responsiveness

Pricing flexibility

Faster negotiation cycles

Ability to meet shifting demand

Vendors operate in more dynamic environments, influenced by consumer trends and inventory turnover.

3. Procurement and Inventory Management

Supplier management:

Controls input costs and prevents production slowdowns.

Ensures manufacturing teams receive materials exactly when needed.

Impacts forecasting, stocking levels, and operational efficiency.

Vendor management:

Aligns product availability with real-time sales performance.

Supports demand planning and last-mile delivery.

Helps avoid overstock and shortages at distribution or retail levels.

Both groups are critical, but each requires different KPIs, contract structures, and visibility tools.

Learn more about: Direct Procurement Risk Management Strategies Explained

Quick Recap Table: Vendor vs Supplier

| Category | Supplier | Vendor |

|---|---|---|

| Supply-Chain Role | Provides raw materials or components | Sells finished goods or services |

| Position in Chain | Start of production cycle | End of distribution cycle |

| Relationship Focus | Stability, consistency, long-term supply | Flexibility, pricing, market responsiveness |

| Impact on Operations | Affects production schedules | Affects sales, customer fulfillment |

| Primary Goal | Ensure production readiness | Drive sell-through and availability |

“This distinction also influences how you store, request, and update critical documentation, from compliance artifacts to contracts.

Platforms like Auditive are built around solving this exact operational friction, helping teams organize and maintain third-party records with far less manual effort.”

How Vendors and Suppliers Work Together

Even though vendors vs suppliers serve different functions, the relationship between them is interdependent and often strategic. Their combined workflow directly shapes product quality, fulfillment speed, and operational stability.

Supply Chain Integration

Suppliers set the foundation by delivering raw materials or components that vendors rely on to assemble, finish, or distribute goods.

Vendors depend on timely supplier output to maintain production cycles and avoid bottlenecks or inventory gaps.

Aligned timelines and shared visibility reduce last-minute disruptions and help uphold consistent delivery guarantees across B2B and B2C channels.

When both sides operate in sync, supply chains become predictable, scalable, and easier to optimize.

Risk Mitigation and Strategic Partnerships

Stable supplier relationships help prevent shortages, quality variations, or sudden cost escalations.

Flexible vendor partnerships allow businesses to adapt quickly to market shifts or demand spikes.

Shared data and collaborative planning improve visibility, making it easier to anticipate risks before they affect downstream operations.

Together, these partnerships create resilience, ensuring organizations can maintain quality, efficiency, and long-term stability even under pressure.

Also Read: Top Supply Chain Risks and Mitigation Strategies

And this coordination between vendors and suppliers only works when the underlying controls, evidence, and risk signals stay aligned.

That’s where Auditive fits naturally, its automated monitoring and control-tracking make it easier to see whether both vendor and supplier activities meet the security and operational standards your teams rely on.

How to Decide Between a Vendor and a Supplier

Choosing between a vendor and a supplier directly affects procurement efficiency, cost stability, and how reliably you can meet customer demand.

Nature of the business

Manufacturers depend on suppliers for core inputs, steel, chemicals, components, because their operations rely on consistent raw-material quality. Retailers, on the other hand, work with vendors that provide finished goods or operational essentials, allowing them to expand product lines quickly without managing production.

Procurement needs

If your priority is bulk inputs for production, suppliers are the operational fit. If you need ready-to-sell inventory or category expansion, vendors offer speed and lower onboarding friction. The right choice also impacts delivery reliability and how smoothly your supply chain scales.

Customer demands

In markets where product demand shifts quickly, companies often use both partner types, suppliers for material stability and vendors for fast assortment updates.

Choosing accurately shapes cost control, lead times, and overall supply performance.

Where Auditive Fits Into Your Vendor–Supplier Decision

Vendor and supplier relationships only work when you can verify how each partner handles security, processes, and operational risk. That’s where Auditive removes the guesswork.

Auditive centralizes all third-party assessments, whether they’re vendors providing finished services or suppliers supporting your core operations, so your team gets a single, verified view of each partner’s risk posture. Instead of chasing documents or relying on manual spreadsheets, Auditive automatically maps evidence, tracks gaps, and highlights control weaknesses using real-time signals and prebuilt framework logic.

For businesses working with multiple external partners, this means you can evaluate a supplier’s operational reliability and a vendor’s security readiness with the same level of clarity, speed, and audit-ready accuracy.

Must Read: Operational Risk Management: Overview and Guide

Final Thoughts

Choosing between a vendor and a supplier is ultimately a decision about what your business needs at each stage of its operations. Suppliers keep production moving by delivering critical inputs, while vendors support downstream functions with ready-to-use products and services. When both roles are evaluated clearly, organizations can structure stronger procurement strategies, reduce operational delays, and build more predictable fulfillment cycles.

Auditive gives teams that level of visibility, helping them assess, verify, and monitor external partners with the same rigor, regardless of where they fall in the supply chain. If your business wants a clearer, more reliable way to evaluate third-party relationships, Auditive provides the structure to do it confidently.

Schedule a demo with Auditive to see how automated assessments and real-time insights strengthen your vendor and supplier decisions.

FAQs

1. How do vendors and suppliers impact different parts of the supply chain?

Suppliers influence early-stage operations like manufacturing, while vendors affect sales, fulfillment, and customer delivery by providing finished goods or services.

2. Is it common for a company to work with both vendors and suppliers?

Yes. Most companies rely on suppliers for inputs and vendors for end-stage inventory or service needs, depending on how broad or complex their operations are.

3. Does choosing a supplier over a vendor change contract or oversight requirements?

It can. Supplier contracts often focus on production quality and timing, while vendor agreements emphasize final deliverables, service levels, and customer impact.

4. What risks differ between vendors and suppliers?

Supplier risks often relate to production delays or material quality, while vendor risks involve service continuity, data handling, or customer-facing performance issues.

5. How can Auditive support vendor and supplier evaluations?

Auditive centralizes assessments, verifies evidence, and highlights partner risks in real time, making it easier to evaluate both vendor and supplier performance with consistent criteria.