Direct Procurement Risk Management Strategies Explained

As supply chains are more interconnected than ever, direct procurement risk management has become a cornerstone of business resilience. Direct procurement, the sourcing of raw materials, components, and goods essential for production, directly impacts a company’s ability to deliver quality products on time. However, this critical function comes with its share of risks, from supplier disruptions and fluctuating market prices to compliance issues and logistical challenges.

Organizations that fail to manage these risks effectively face not just financial setbacks but also reputational damage and operational inefficiencies. On the other hand, those that establish structured procurement risk management strategies can secure reliable supply, strengthen supplier relationships, and maintain a competitive edge.

This blog unpacks the essentials of direct procurement, explores its challenges, and outlines strategies businesses can adopt to mitigate risks while ensuring long-term stability and growth.

Key takeaways:

Direct procurement is critical but highly exposed to risks like supply chain disruption, cost volatility, compliance, and supplier dependency.

Strategies such as supplier diversification, hedging, and vendor development help mitigate risks.

Vendor risk management and Trust Centers strengthen transparency and trust across procurement ecosystems.

Technology-driven solutions like AI and blockchain provide resilience and predictive insights.

Auditive empowers procurement leaders with visibility, compliance, and risk intelligence, turning uncertainty into opportunity.

What is Direct Procurement?

Direct procurement refers to the purchasing of goods and materials that directly feed into the production of a company’s end products. These purchases form the backbone of manufacturing and operations, making them vital for cost efficiency, quality control, and supply chain stability.

Unlike indirect procurement, which covers day-to-day operational needs such as office supplies, marketing services, or software, direct procurement zeroes in on securing the essential inputs needed to produce goods at scale.

Because of its direct link to production outcomes, businesses approach direct procurement with very specific objectives, such as:

Ensuring a reliable supply of materials to avoid production delays.

Controlling costs through effective supplier negotiations and bulk purchasing.

Maintaining strict quality standards to deliver consistent and reliable products.

Strong supplier relationships are also central to direct procurement. Long-term partnerships often translate into better pricing, improved collaboration, and faster responsiveness during unexpected disruptions, helping companies stay resilient in the face of uncertainty.

Why is Direct Procurement So Important?

Direct procurement is more than just a cost center, it directly shapes a company’s profitability, efficiency, and long-term competitiveness. Because it directly impacts the cost of goods sold (COGS), every decision in this area has a ripple effect on margins, product quality, and supply chain resilience. An optimized procurement strategy not only lowers costs but also strengthens the foundation of sustainable business growth.

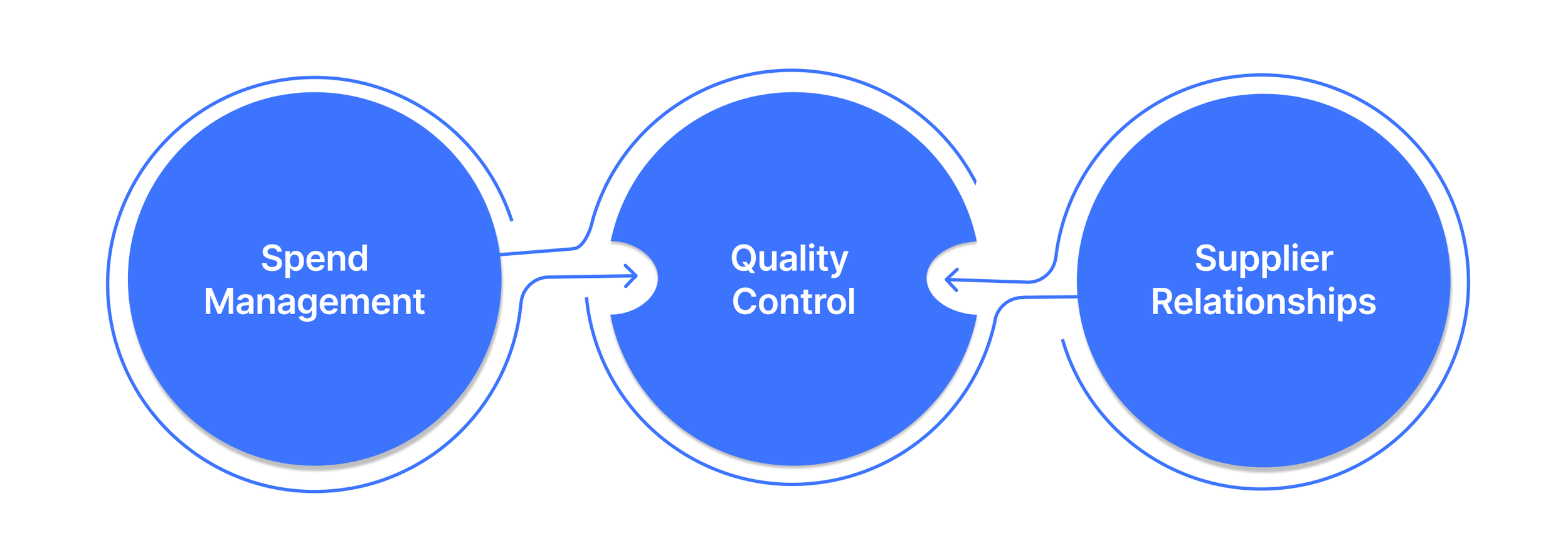

Here are three core reasons why direct procurement holds such importance:

Spend Management: Buying directly from manufacturers or primary suppliers eliminates intermediaries, reduces markup costs, and opens the door to bulk purchasing discounts. This streamlined sourcing approach translates into significant cost savings and healthier margins.

Quality Control: Close collaboration with trusted suppliers ensures that raw materials and components meet precise specifications. This reduces defects, enhances product consistency, and maintains high quality standards, an especially critical factor in industries like manufacturing, pharmaceuticals, and electronics.

Supplier Relationships: Strong, long-term partnerships with suppliers lead to better contract terms, priority access to scarce materials, and enhanced stability in the supply chain. In times of market volatility or raw material shortages, these relationships can be the difference between disruption and continuity.

In essence, direct procurement is a strategic lever, one that helps businesses control costs, safeguard quality, and build resilience against uncertainty.

Few Examples of Direct Procurement

Direct procurement usually falls into three major categories, raw materials, components, and finished goods, each playing a crucial role in keeping production running smoothly.

Raw Materials

These form the foundation of most products. Metals, plastics, and chemicals are classic examples. In the automotive sector, steel and aluminum are indispensable for building frames, while plastics are widely used for interiors and trims.

Components

These are pre-manufactured parts that get assembled into the final product. For example, car manufacturers source electrical wiring, microchips, and LCD screens from specialized suppliers to integrate into vehicles.

Finished Goods

Though less common, some businesses procure finished goods as part of direct procurement. Automakers often purchase pre-made tires from external vendors rather than producing them in-house, saving time and resources.

By covering these categories, direct procurement ensures that businesses have the critical inputs for production, directly influencing cost control, quality assurance, and overall supply chain efficiency.

Stages of Direct Procurement

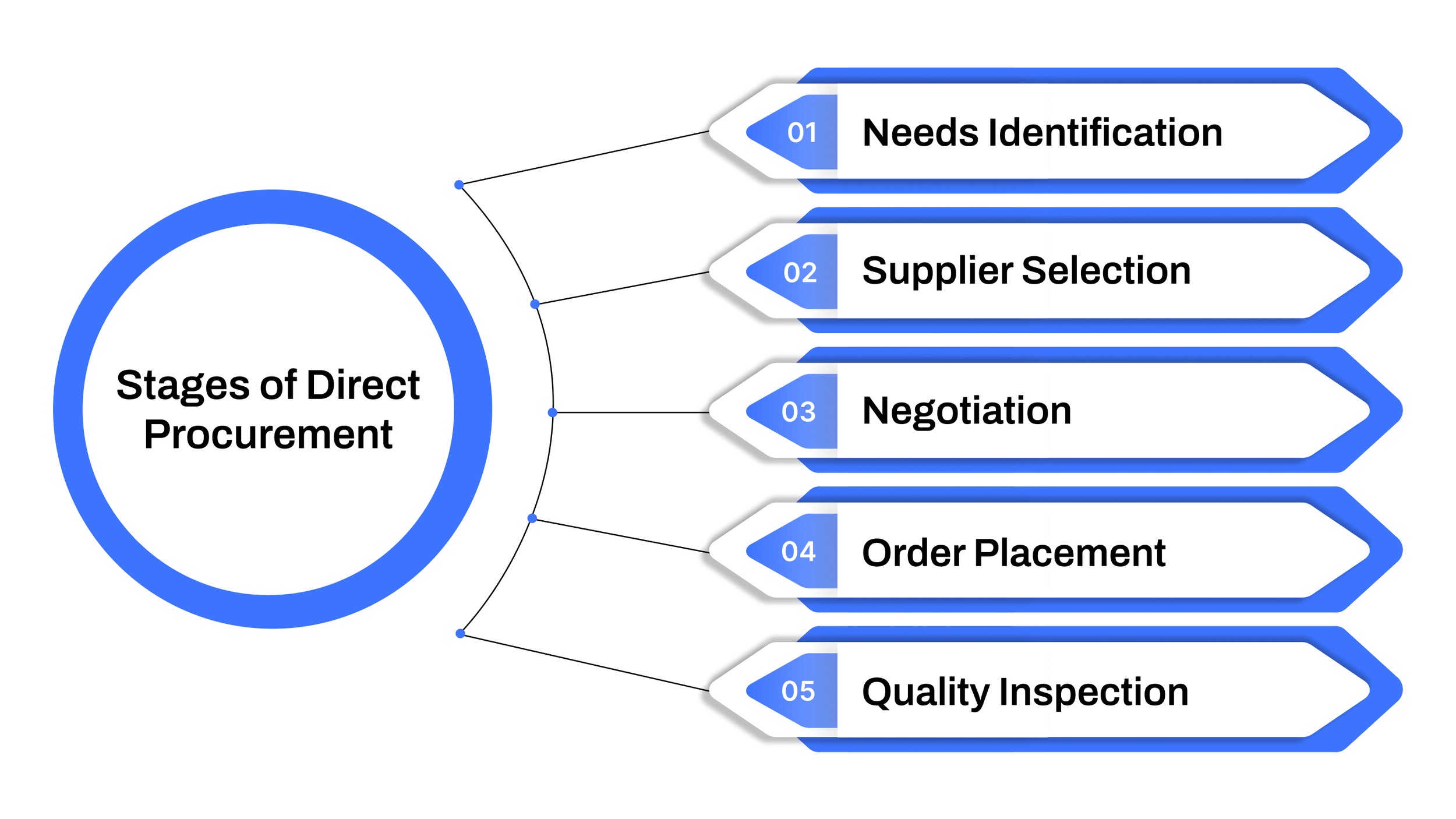

A well-structured direct procurement process is essential for securing the right materials, managing costs, and ensuring consistent product quality. Although the exact workflow may differ from industry to industry, the process typically includes five core stages:

1. Needs Identification

The first stage is about pinpointing what materials are required, when they’re needed, and in what quantities. Procurement teams analyze production schedules, assess current inventory, and evaluate supply chain vulnerabilities to avoid surprises. A mistake at this step can ripple through the business, shortages can halt production, while excess orders tie up capital and increase storage costs.

Key considerations in this stage include:

Reviewing production forecasts to predict upcoming demand.

Checking current inventory levels to avoid duplication or shortage.

Identifying supply chain risks such as seasonal delays or geopolitical uncertainties.

Striking the right balance here ensures procurement aligns with both operational needs and cost efficiency.

2. Supplier Selection

Not all suppliers bring the same value, and choosing the right one often determines long-term success. While cost matters, reliability, flexibility, and responsiveness are equally critical. Businesses increasingly focus on building relationships with suppliers who can adapt to fluctuations in demand and maintain consistent quality standards.

To strengthen supplier selection, businesses often:

Conduct supplier audits to verify reliability and compliance.

Request product samples or pilot orders to check quality.

Assess financial stability and scalability for long-term partnerships.

By looking beyond price, organizations reduce the risk of disruptions and secure sustainable supplier relationships.

3. Negotiation

Once potential suppliers are identified, negotiations set the terms for partnership. This isn’t just about driving prices down, it’s about finding a win-win structure that benefits both sides. Effective negotiations balance cost efficiency with commitments to quality, delivery speed, and flexibility.

Smart negotiation strategies include:

Focusing on total value delivered, not just unit price.

Clarifying service levels, warranties, and after-sales support.

Ensuring payment terms and delivery schedules align with business needs.

This stage helps organizations secure competitive agreements while building trust and long-term collaboration.

4. Order Placement

With agreements finalized, the next step is formalizing the transaction through purchase orders (POs). These documents capture crucial details such as product specifications, quantities, pricing, and delivery schedules. A clear, well-structured PO reduces the risk of errors that could cause shipment delays or incorrect deliveries.

Best practices for this stage include:

Using procurement software to standardize and automate POs.

Ensuring clear, unambiguous documentation of requirements.

Confirming acknowledgments from suppliers before processing.

Strong order placement practices provide clarity for suppliers and assurance for buyers, minimizing costly missteps.

5. Delivery and Quality Inspection

The final stage closes the loop by ensuring products arrive on time and meet agreed standards. Even a timely delivery is a failure if the materials don’t meet quality benchmarks. Accepting subpar goods may solve short-term bottlenecks but often leads to higher defect rates, increased waste, or customer dissatisfaction down the line.

Effective quality control involves:

Inspecting deliveries against agreed specifications.

Monitoring defect rates and supplier performance over time.

Holding suppliers accountable for recurring issues with corrective measures.

By enforcing quality and reliability, businesses protect their production processes and reinforce trust across the supply chain.

Managing these five stages effectively requires more than procedural discipline. Businesses need real-time visibility, proactive risk management, and automated compliance tracking. This is where Auditive supports procurement leaders, streamlining vendor risk management, strengthening oversight, and embedding trust throughout every procurement stage.

Strategies to Improve Direct Procurement

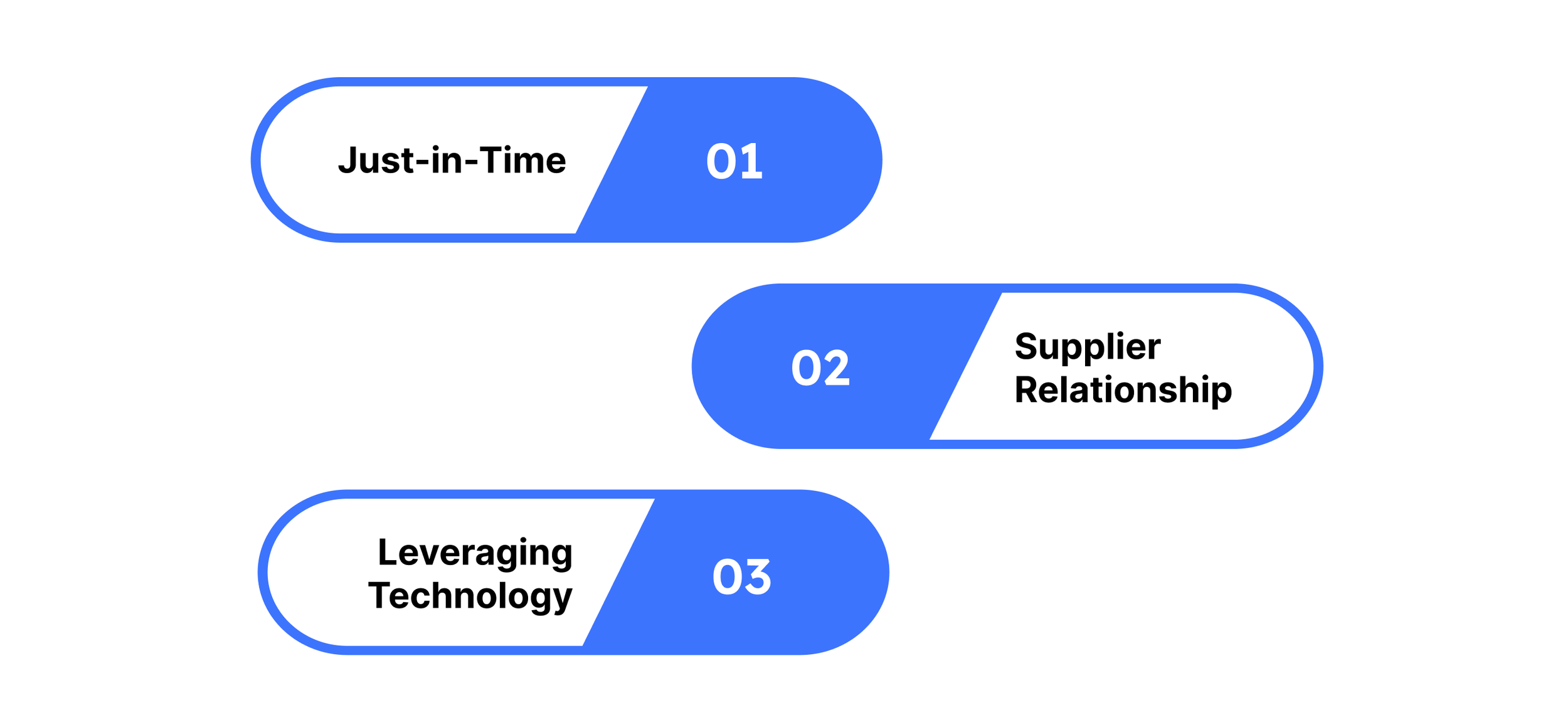

Optimizing direct procurement is not just about reducing costs, it’s about building resilience, improving efficiency, and ensuring that production lines never miss a beat. Businesses can strengthen procurement operations by focusing on three critical strategies:

Read more about: Procurement Risk Management

1. Just-in-Time (JIT) Inventory Management

Just-in-Time (JIT) inventory management ensures that materials arrive when they are needed, rather than being stored in advance. This minimizes holding costs, reduces waste, and frees up working capital.

How to implement JIT effectively:

Strengthen demand forecasting: Leverage historical data, seasonal trends, and predictive analytics.

Improve supplier coordination: Partner with reliable suppliers who can guarantee timely deliveries.

Enhance logistics efficiency: Align transport and warehousing processes for rapid turnaround.

JIT creates leaner operations, but it requires precise forecasting and dependable suppliers. Any delay can cause production stoppages, making supplier reliability non-negotiable.

2. Supplier Relationship Management (SRM)

Supplier Relationship Management (SRM) focuses on building trust-based, long-term partnerships instead of transactional interactions. Strong supplier relationships lead to better pricing, higher reliability, and faster recovery during disruptions.

How to build stronger supplier relationships:

Consistent communication: Regular check-ins to align on expectations.

Performance metrics: Track delivery timelines, product quality, and responsiveness.

Joint improvements: Collaborate on efficiency, cost savings, and innovation.

A solid SRM approach transforms suppliers into strategic allies who are more likely to prioritize your business when demand surges or supply chain risks arise.

3. Leveraging Technology and Automation

Modern procurement thrives on data-driven insights and automation. Technology eliminates inefficiencies, reduces human error, and provides visibility across the supply chain.

Key ways to use technology in procurement:

Procurement software: Centralize sourcing, contracts, and supplier tracking.

AI-powered analytics: Forecast demand shifts and identify risks early.

Process automation: Automate repetitive tasks like purchase orders and invoice approvals.

By adopting these tools, procurement teams can shift their focus from firefighting daily issues to driving cost savings, innovation, and long-term strategy.

While these strategies strengthen direct procurement, many organizations struggle with risk visibility across suppliers, compliance monitoring, and disruption preparedness. This is where platforms like Auditive become game-changers, helping businesses move from reactive procurement to proactive, data-backed resilience.

Challenges in Direct Procurement and Solution to Deal with Them

Even the most mature procurement operations face persistent challenges that can disrupt production and weaken overall business performance. Tackling these issues requires a proactive approach, combining smart strategies with continuous improvement.

Below are four of the most common direct procurement challenges and practical ways to address them:

1. Supply Chain Disruptions

Global supply chains are more fragile than they appear. The COVID-19 pandemic, semiconductor shortages, and geopolitical tensions have all shown how quickly production can grind to a halt when critical components become unavailable. Beyond delays, such disruptions create ripple effects like inflated labor costs, expensive expedited shipping, and unhappy customers due to missed delivery deadlines.

Get more info about: Supply Chain Management

Solution:

Diversifying suppliers across regions helps organizations spread their risk and minimize dependence on a single geography. Building strong relationships with multiple manufacturers allows for rapid pivots when one supplier encounters disruption, ensuring business continuity.

2. Fluctuating Material Costs

Unstable raw material prices make budgeting and forecasting highly complex. For companies locked into fixed-price customer contracts, sudden price spikes can squeeze already tight margins. Regulatory changes can also cause unexpected surges in costs, adding further unpredictability to procurement strategies.

Solution:

Businesses can employ financial hedging strategies, futures contracts, and price adjustment clauses in supplier agreements. These tools stabilize input costs and provide flexibility, allowing companies to maintain profitability even when markets shift abruptly.

3. Supplier Relationship Management

Relying too heavily on a single supplier, or struggling with communication and quality control, can introduce serious vulnerabilities. If a supplier faces operational setbacks, the downstream impact can stall production, compromise quality, and damage customer trust.

Solution:

Implementing robust vendor management practices is key. Companies should foster collaborative partnerships through supplier development initiatives, joint improvement programs, and regular performance evaluations. This shifts the relationship from transactional to strategic, driving long-term reliability and innovation.

4. Regulatory Compliance

Modern procurement teams must navigate a maze of compliance requirements, from environmental standards to responsible sourcing regulations. Non-compliance not only risks fines but can also harm a company’s reputation and restrict access to certain markets.

Solution:

Leveraging advanced traceability solutions, such as blockchain and digital supply chain tools, provides visibility into the origins and handling of materials. These technologies simplify audits, reduce compliance costs, and enhance transparency for customers who increasingly value ethical sourcing.

Addressing these challenges is no longer about reactive firefighting, it requires integrated, intelligent systems that proactively identify risks before they escalate. This is where Auditive brings unique value. By combining real-time risk insights, vendor monitoring, and advanced compliance tools, Auditive helps procurement teams not only manage but also anticipate risks, ensuring resilient and future-ready supply chains.

Auditive: Elevating Direct Procurement Risk Management

Procurement today is no longer just about negotiating contracts or securing materials, it’s about maintaining resilience in the face of uncertainty. Organizations need visibility, agility, and a proactive stance on risk. This is where Auditive delivers value.

Auditive’s RiskOps approach integrates seamlessly into procurement workflows, providing real-time monitoring, risk intelligence, and vendor management capabilities. Instead of reacting to supply chain shocks or compliance hurdles after they occur, businesses can anticipate risks and act before disruptions escalate.

Key ways Auditive strengthens direct procurement risk management include:

End-to-End Visibility: Centralizes supplier, contract, and compliance data for transparent oversight.

Vendor Risk Management: Proactively evaluates supplier reliability and performance, reducing dependency risks.

Regulatory Confidence: Embeds traceability and compliance checks, simplifying audits and avoiding penalties.

Adaptive Insights: Uses AI-driven analytics to detect patterns, anticipate material cost fluctuations, and flag potential supply disruptions.

By aligning risk management with procurement strategy, Auditive helps organizations move beyond short-term fixes. The result is a procurement ecosystem that is predictable, resilient, and built on trust, enabling leaders to focus on growth rather than firefighting.

Conclusion

Direct procurement is the backbone of production and business continuity, but it is also one of the most risk-exposed functions in the enterprise. From supply chain disruptions and volatile material costs to supplier dependency and regulatory compliance, the challenges are multi-dimensional. Businesses that rely on outdated, reactive processes will continue to struggle with inefficiencies and rising risks.

A modern procurement strategy requires more than just transactional oversight, it calls for robust vendor risk management practices and transparent governance models that build confidence across the value chain. Leveraging tools like a Trust Center empowers organizations to create a transparent, accountable environment where risks are monitored, assessed, and acted upon with speed.

This is precisely where Auditive brings unmatched value. By embedding risk intelligence into procurement workflows, offering end-to-end visibility, and ensuring compliance confidence, Auditive equips organizations with the agility to turn procurement risks into opportunities.

Future-proof your procurement with Auditive, where resilience, trust, and intelligence converge.

FAQs

1. What is the biggest risk in direct procurement?

The most significant risk is supply chain disruption, as it can halt production and impact revenue. However, risks such as fluctuating material costs and regulatory non-compliance are equally critical.

2. How can companies manage supplier-related risks effectively?

Implementing structured vendor risk management practices, diversifying suppliers, and building strong communication frameworks reduce dependency and improve supply stability.

3. Why is regulatory compliance a challenge in direct procurement?

Global operations must adhere to multiple regulatory standards. This creates complexities in documentation, traceability, and audits. Non-compliance can result in fines, delays, and reputational damage.

4. What role does technology play in procurement risk management?

Advanced solutions like AI-driven analytics, blockchain, and procurement platforms enhance visibility, predict material cost fluctuations, streamline compliance, and improve overall supply chain resilience.

5. How does Auditive support procurement teams?

Auditive provides real-time monitoring, supplier risk assessment, compliance tracking, and a centralized Trust Center, enabling organizations to proactively identify, manage, and mitigate procurement risks.