AI in Supply Chain Risk Management Strategies

Supply chain disruptions can strike from anywhere, such as geopolitical tensions, raw material shortages, transportation delays, or sudden shifts in demand. For modern enterprises, managing these risks isn’t just about reacting quickly; it’s about anticipating them before they happen. This is where AI in supply chain risk management becomes a game-changer.

Artificial intelligence empowers businesses to transform reactive supply chains into proactive, data-driven ecosystems. By analyzing millions of data points, from supplier performance and financial health to weather patterns and market trends AI enables decision-makers to detect potential threats, assess vulnerabilities, and implement mitigation strategies in real time.

But adopting AI isn’t just a technological move, it’s a strategic shift. It’s about turning uncertainty into insight and complexity into clarity. In this blog, we’ll explore how AI is revolutionizing supply chain risk management, the key strategies for successful implementation, and how intelligent solutions like Auditive help enterprises stay ahead of disruptions while strengthening trust, transparency, and operational resilience.

Key Takeaways:

AI transforms supply chains from reactive to predictive systems.

Reliable data and ongoing model training are key to effective AI-driven decisions.

Human expertise remains crucial to validate and apply AI insights.

Vendor risk management and transparency ensure stronger supplier relationships.

Auditive’s Trust Center empowers businesses to build intelligent, resilient, and compliant supply chains.

How AI Is Redefining Supplier Risk Management

In the past, choosing a supplier was mostly about finding the lowest price. But as businesses evolved, especially in retail and consumer goods, the definition of a good supplier has expanded. Now, companies look for partners who deliver more than just cost savings. They want suppliers who are reliable, scalable, and aligned with their sustainability and ESG goals.

Global challenges have only intensified this shift. Events like the pandemic, climate crises, and geopolitical tensions have exposed the fragility of global supply chains. Billions of dollars can hinge on a single supplier’s ability to perform consistently, making effective risk management more important than ever. Yet, despite its necessity, comprehensive supplier risk management often remains too complex, expensive, or fragmented for many organizations to execute effectively.

That’s where Artificial Intelligence (AI) steps in, transforming supplier management from reactive problem-solving to proactive insight. AI-powered systems can analyze vast amounts of supplier data, detect early warning signs, and help procurement teams make smarter, faster decisions.

Recent research supports this shift:

70% of Chief Procurement Officers (CPOs) report an increase in supply chain risks and disruptions.

AI-driven supplier management has been identified as a leading strategy to create value and resilience.

A McKinsey survey found that companies using AI in supply chain and inventory management saw revenue boosts exceeding 5%.

AI is no longer a futuristic concept, it’s becoming the new backbone of supplier risk management, helping businesses anticipate risks, adapt quickly, and thrive in an unpredictable world.

How AI Transforms the Supplier Selection and Risk Management Lifecycle

Artificial Intelligence (AI) is redefining the way organizations manage suppliers, from identifying potential partners to continuously monitoring performance and risk. Rather than relying on traditional, time-consuming processes, AI enables data-driven decision-making that’s faster, smarter, and far more adaptable to real-world challenges. Let’s explore how AI is optimizing each stage of supplier selection and risk management.

1. Smarter Market analyzis and Supplier Discovery

AI has dramatically accelerated the way companies identify and assess potential suppliers. According to industry research, AI-powered tools can reduce supplier identification time by up to 90%, allowing teams to act quickly in dynamic markets.

Here’s how AI supports this phase:

Data-driven insights: AI systems pull information from financial records, sustainability reports, patents, and even online reviews to paint a 360-degree picture of potential suppliers.

Predictive analytics: By analyzing market trends and performance patterns, AI helps forecast which suppliers will remain stable and reliable.

Continuous updates: Unlike static databases, AI platforms update supplier data in real time, keeping insights fresh and accurate.

For instance, global enterprises like Unilever use AI to scan supplier ecosystems for financial stability, innovation potential, and sustainability ratings, ensuring continuity even in uncertain conditions. Similarly, Koch Industries employs AI tools that assess data down to the SKU level, identifying alternative suppliers and reducing dependency on lengthy RFQ processes.

By transforming supplier discovery from a manual task into a strategic capability, AI empowers organizations to make faster, better-aligned sourcing decisions.

2. Intelligent Supplier Evaluation and Qualification

Once potential suppliers are identified, AI makes the qualification process more efficient and objective. Instead of relying solely on self-reported data, AI integrates:

Compliance records

Financial performance indicators

Historical delivery accuracy

Certifications and audit findings

These factors are analyzed holistically to rank and score suppliers based on reliability, risk exposure, and performance potential. The outcome is a smarter, transparent qualification process that reduces human bias and supports better governance.

3. Proactive Risk Assessment and Continuous Monitoring

AI’s greatest contribution to supplier management lies in its ability to perform real-time risk monitoring. Machine learning models continuously analyze supplier operations, global market conditions, and external threats, from financial instability to cybersecurity breaches or geopolitical disruptions.

Key benefits include:

Predictive warnings: AI can detect early indicators of disruption, such as raw material shortages or natural disasters, allowing teams to act before issues escalate.

Comprehensive visibility: Modern AI tools consolidate financial, operational, and compliance data into unified dashboards for better decision-making.

Automated communications: AI chatbots now handle routine supplier queries and updates, freeing human teams for high-value collaboration.

For example, companies like Walmart use AI-driven chatbots to negotiate with smaller “tail-end” suppliers, streamlining procurement and saving significant manual effort. Similarly, AI-based platforms can issue early alerts for disruptions in regions affected by geopolitical instability, helping businesses stay one step ahead.

4. Strengthening Supplier Relationships through AI

AI doesn’t just manage risk, it builds trust. By analyzing communication patterns, contract performance, and feedback loops, AI can help identify opportunities to improve vendor collaboration. It ensures transparency and responsiveness, promoting a healthier partnership between buyers and suppliers.

Moreover, AI-assisted insights allow procurement teams to proactively address potential bottlenecks, creating a more resilient and cooperative supply network that thrives on shared visibility and accountability.

5. Optimizing the Supply Chain for Resilience

Beyond individual supplier management, AI helps businesses optimize the entire supply chain. By simulating different operational scenarios, such as shipping delays, demand surges, or raw material shortages, AI tools identify the best path forward with minimal disruption.

Scenario modeling: AI runs simulations based on real-time data to forecast outcomes of potential supply chain changes.

Inventory optimization: AI-driven demand forecasting ensures products are stocked efficiently without over- or under-ordering.

Cost reduction: By analyzing transportation routes, warehouse operations, and supplier efficiency, AI helps companies lower operational costs.

For instance, Home Depot leveraged Google’s AI and machine learning technologies to enhance its inventory management and logistics, ensuring timely product availability during global shipping disruptions.

AI’s ability to analyze complex data patterns transforms reactive supply chains into proactive, adaptable ecosystems ready for anything the market throws their way.

Auditive empowers businesses to take the power of AI further through continuous Vendor Risk Management and Trust Center capabilities. By integrating AI-driven analytics, organizations can automatically monitor vendor performance, detect early warning signs, and ensure compliance across all partnerships.

Also Read: Understanding Supply Chain Attacks: Key Insights and Examples

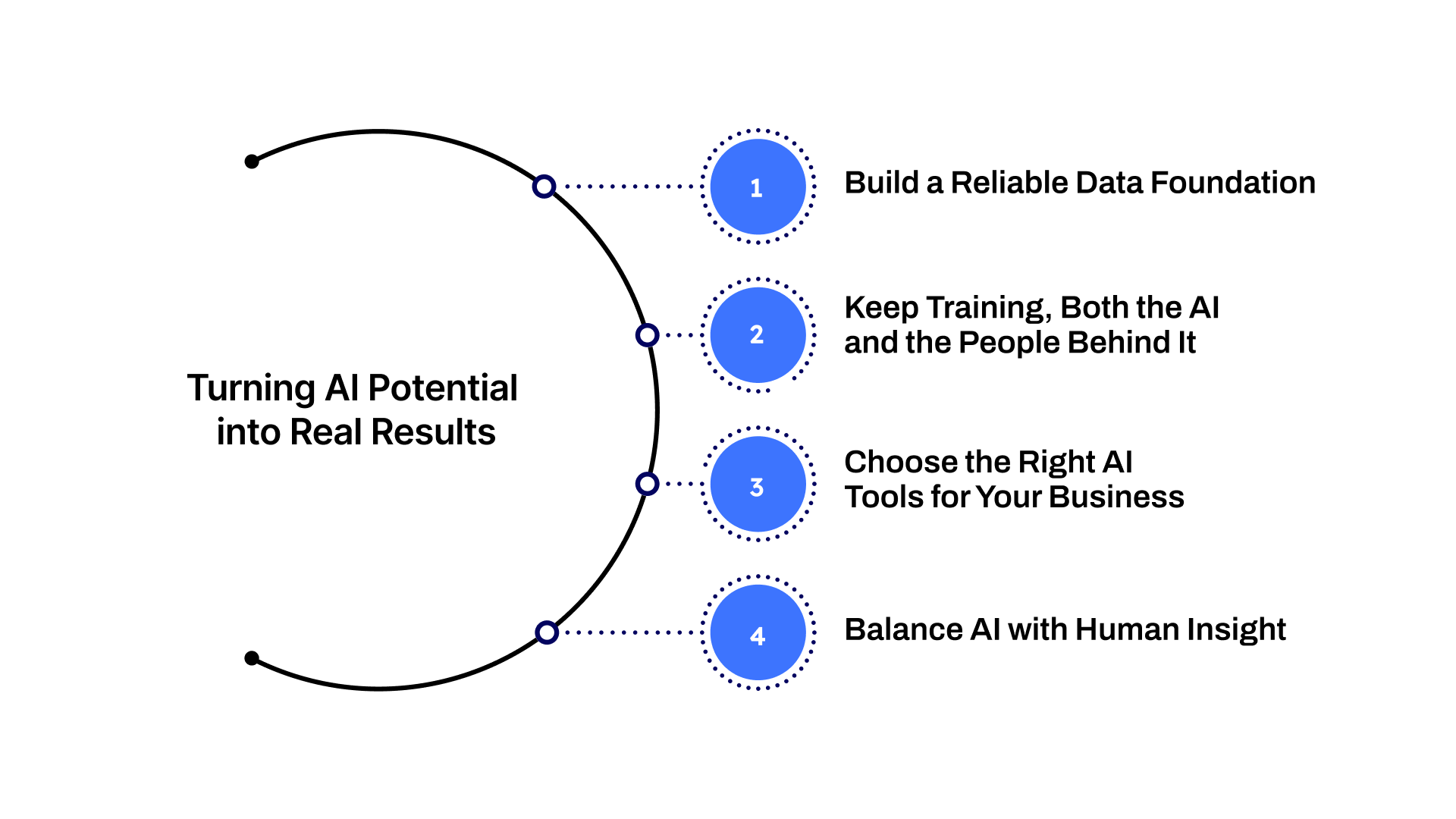

Turning AI Potential into Real Results

Artificial intelligence is quickly reshaping how businesses manage supply chains, but turning ideas into measurable impact takes more than adopting the latest tool. To truly transform supplier management and procurement, organizations must combine the right data, technology, and human expertise. Here’s how you can make AI in supply risk management actually work for your business:

1. Build a Reliable Data Foundation

AI is only as good as the data behind it. When your supply chain data is outdated, incomplete, or scattered across silos, even the smartest AI model will struggle to deliver accurate insights.

To make AI effective:

Unify and clean your data: Integrate procurement, logistics, and vendor data into a single system.

Establish governance: Define clear data ownership and quality standards.

Invest in scalability: Use cloud-based data lakes to ensure real-time updates and easy access.

Without a strong data backbone, your AI tools risk producing more noise than value. The better your data, the sharper your decisions.

2. Keep Training, Both the AI and the People Behind It

AI systems learn from the data you feed them, and that learning must evolve as your market, vendors, and risks change. Biases or outdated inputs can easily skew results. Regularly retrain models using fresh, relevant data to improve prediction accuracy and reduce risk blind spots.

But AI training isn’t just about algorithms, your team plays a vital role too. Equip your procurement and risk management teams with the skills to interpret AI-driven insights and make smarter, faster calls. After all, AI amplifies human judgment; it doesn’t replace it.

3. Choose the Right AI Tools for Your Business

Not every company needs a custom-built AI engine. Sometimes the best approach is enhancing what you already have.

Consider three key pathways:

Platform Upgrades: Leverage supplier management systems that already embed AI for risk scoring, contract analyzis, or spend visibility.

ProcureTech Solutions: Explore niche tools that specialize in AI-driven vendor scanning or compliance automation.

Custom Development: If you have a data science or ML team, build tailored models aligned to your business goals.

Selecting the right mix depends on your existing infrastructure, risk exposure, and long-term innovation strategy.

4. Balance AI with Human Insight

AI can flag patterns, anomalies, or risks faster than any manual process, but context still matters. Human expertise is essential for validating findings, interpreting nuances, and making judgment calls that algorithms can’t.

For example, while AI might detect a financial irregularity with a vendor, only a human expert can determine whether it’s a genuine red flag or a contextual anomaly. The goal isn’t to replace people with AI but to empower them with deeper, data-backed insights.

When humans and machines collaborate effectively, risk management becomes proactive rather than reactive.

Learn more about: Identifying and Managing Supply Chain Vulnerabilities

How Auditive Elevates AI-Driven Supply Chain Risk Management

Implementing AI in supply chain risk management isn’t just about algorithms and automation, it’s about building trust, transparency, and control. That’s where Auditive steps in.

Auditive helps enterprises turn complex supplier ecosystems into clear, data-driven networks powered by AI intelligence and human insight. Our solutions enable you to:

Identify risks early through predictive AI analytics that continuously monitor supplier performance and compliance.

Centralize data visibility across vendors, contracts, and operations, creating a single source of truth for informed decision-making.

Enhance resilience with real-time alerts and automated risk scoring, so teams can act before disruptions escalate

Integrate seamlessly with your existing procurement and ERP systems for a smooth, scalable adoption of AI.

At Auditive, we believe that technology is only as powerful as the trust it builds. Our platform combines advanced AI capabilities with enterprise-grade security and compliance, helping organizations confidently navigate risk, strengthen supplier relationships, and drive smarter outcomes.

Empower your supply chain with intelligence that works for you, discover how Auditive transforms risk into opportunity.

Conclusion

Artificial intelligence is no longer a futuristic concept, it’s the foundation of smarter, more agile supply chains. From predictive analytics and supplier monitoring to automated decision-making, AI empowers organizations to identify risks before they escalate and take proactive measures to protect business continuity. However, technology alone isn’t enough. Success depends on the right blend of AI-powered insights, vendor risk management, and human expertise to interpret and act on those insights effectively.

That’s where Auditive comes in. With its Trust Center and advanced AI-driven risk management tools, Auditive helps enterprises strengthen transparency, enhance collaboration, and secure every link of their supply chain. Whether you’re optimizing procurement or improving compliance visibility, Auditive ensures you’re always one step ahead in mitigating risks and maintaining trust across your vendor ecosystem.

Partner with Auditive to integrate intelligent AI solutions that transform risk into resilience and strategy into success.

FAQs

1. What is AI supply chain risk management?

AI supply chain risk management uses artificial intelligence and machine learning to analyze data, predict potential disruptions, and help businesses take preventive actions before risks affect operations.

2. How does AI help identify supply chain risks?

AI continuously monitors supplier performance, market conditions, and global events, identifying early warning signs of issues like delivery delays, quality failures, or financial instability.

3. What are the benefits of using AI in vendor risk management?

AI enhances accuracy, speeds up risk detection, reduces manual effort, and improves decision-making through data-driven insights and real-time analytics.

4. Can AI replace human judgment in supply chain management?

Not entirely. While AI provides valuable insights and automation, human expertise is essential for interpreting complex data and making strategic decisions.

5. How can Auditive support AI-driven supply chain risk management?

Auditive offers AI-powered tools and a Trust Center that enable proactive vendor monitoring, risk assessment, and compliance tracking, helping businesses build secure, transparent, and resilient supply chains.