Supply Chain Risk Management Strategies and Examples

Supply chain disruption has become a top concern for procurement leaders: in a recent Gartner survey, 42% of sourcing leaders identified supply disruptions as their primary risk. For organizations in healthcare, finance, and education, that risk isn’t just about inventory; it puts sensitive systems and critical services on the line.

This makes ongoing risk monitoring essential: real-time visibility into third‑party performance and supplier health isn’t a luxury; it’s a foundation for building resilient, data-driven supply chains.

In this blog, we’ll explore practical strategies and real-world supply chain risk management examples that security and procurement teams can apply right away.

Before we dive in:

Supply chain risks are inevitable; resilience requires continuous monitoring and proactive strategies.

Metrics like Time to Recover (TTR) and Time to Survive (TTS) help quantify disruption impact.

Diversified sourcing, inventory buffers, and nearshoring reduce dependency on high-risk regions.

Auditive’s Trust Center centralizes vendor monitoring, providing real-time alerts and verified risk data.

Integrating strategic planning with ongoing monitoring ensures faster responses and operational continuity.

Understanding Supply Chain Risk Management

Disruptions in global supply chains can halt production, delay critical services, and damage brand trust. Just-in-time inventory systems, while efficient, leave little margin for error.

Supply Chain Risk Management (SCRM) is the process of identifying, assessing, and mitigating risks across suppliers, logistics, and distribution channels to prevent operational and reputational impacts. It focuses on:

Monitoring supplier reliability and financial health

Implementing backup suppliers or alternative transport routes

Tracking risk exposure across all tiers of the supply chain

For sectors like healthcare, finance, and education, real-world supply chain risk management examples show that proactive risk management reduces downtime, prevents data and operational breaches, and ensures uninterrupted service delivery.

Why Strong Supply Chain Risk Management Matters

Effective supply chain risk management isn’t just about process efficiency, it’s about anticipating disruptions before they happen. Modern business flows, often just-in-time, leave little margin for error: a single broken link can delay production, increase costs, and impact service delivery.

Key reasons SCRM is critical:

Proactive risk identification: Companies ask, “What could go wrong?” and prepare strategies before disruptions occur.

Faster mitigation decisions: Organizations with solid SCRM programs can respond immediately when a supplier or logistical issue arises.

Global complexity: With suppliers, logistics, and regulations spanning multiple countries, risks now include national security, environmental factors, and regulatory obligations.

Cost and operational efficiency: Proper SCRM balances risk with business goals, reducing unnecessary expenses while maintaining resilience.

Practical supply chain risk management examples include supplier diversification, scenario planning, buffer inventories, and automated monitoring, each designed to maintain continuity and strengthen resilience in sectors like healthcare, finance, and education.

Key Supply Chain Risks Every Organization Should Track

Understanding the types of supply chain risks is the first step toward effective mitigation. These risks fall into internal and external categories, each with unique impacts on operations, finances, and reputation.

Internal Risks

Risks originating within the organization can often be managed directly but still have serious consequences if ignored:

Operational Risks: Inefficient processes, bottlenecks, and quality issues can delay production or distribution.

Financial Risks: Cost fluctuations, cash flow problems, or demand volatility can strain supplier relationships and inventory planning.

Manufacturing Risks: Equipment breakdowns, production delays, and labor shortages can create domino effects in product availability.

Contract and Regulatory Risks: Failing to uphold SLAs or contractual terms, including audit rights, can lead to penalties and legal exposure.

External Risks

External risks arise from suppliers, environmental factors, and geopolitical forces outside direct control:

Reputational Risks: Supplier misconduct or failure to meet standards can damage brand trust.

Cybersecurity Risks: Ransomware attacks or IT disruptions can cripple supply chains, as seen in the 2021 Colonial Pipeline incident.

Geopolitical Risks: Tariffs, trade wars, and government instability, like the U.S.-China trade war affecting $380 B in goods, can disrupt sourcing and inflate costs.

Environmental Risks: Natural disasters and climate events can halt operations. NOAA reported 18 separate billion-dollar U.S. disasters in 2022, many impacting supply chains directly.

Why this matters for strategy:

Recognizing these risks is essential when building supply chain risk management. Each type of risk requires tailored oversight, monitoring, and response planning to avoid financial loss, operational downtime, or reputational damage.

Tracking internal operations is one thing, but the majority of supply chain disruptions originate with vendors and external partners. Auditive gives organizations continuous visibility into vendor performance, controls, and risk posture. Its network-based approach allows buyers and vendors to maintain live Trust Profiles.

Learn more about: Understanding Supply Chain Attacks: Key Insights and Examples

Practical Steps for Managing Supply Chain Risks

Managing supply chain disruptions requires more than reactive measures, it demands a structured approach. Here are five actionable steps that illustrate how organizations can mitigate risk effectively, with supply chain risk management examples embedded in each stage.

1. Identify Risks

Understanding potential vulnerabilities is the first step. Methods include:

SWOT Analysis: Highlights internal weaknesses and external threats.

Failure Mode and Effects Analysis (FMEA): Prioritizes risks based on likely impact and occurrence.

ISO 31000 Guidelines: Provides a standardized framework for risk identification.

Successful identification depends on involving cross-functional teams and gathering critical documentation, from supplier contracts to process manuals.

2. Assess Risks

Once identified, risks must be evaluated for impact and likelihood:

Likelihood and Impact: Estimate both probability and operational consequences.

Supplier Risk: Assess financial stability, operational capacity, and resilience plans. Track performance using metrics like on-time delivery and incident rates.

Third-Party Assurance: Verify certifications, quality standards, and risk management practices.

3. Integrate Risk Management into Supply Chain Strategy

Risk considerations should inform everyday decisions and long-term planning. Involving procurement, logistics, finance, IT, and security ensures all risks are addressed and fosters a culture of accountability.

4. Mitigate Risks

Tailor strategies to the type and severity of each risk:

Diversification: Multi-source critical materials to reduce reliance on single suppliers.

Redundancy: Maintain safety stock and backup transportation routes.

Strategic Partnerships: Strengthen communication with key suppliers.

5. Monitor and Review

Continuous oversight is critical:

Use ERP and integrated platforms to track supplier performance and logistics in real time.

Conduct regular reviews to update mitigation strategies as market conditions and supply chain landscapes evolve.

Traditional risk management steps identifying, assessing, mitigating, and monitoring often rely on manual updates and fragmented data. Auditive integrates these processes by continuously monitoring vendors, tracking certifications, and automating evidence collection. This ensures real-time visibility into emerging supply chain risks, so organizations can act immediately on deviations rather than waiting for periodic reviews.

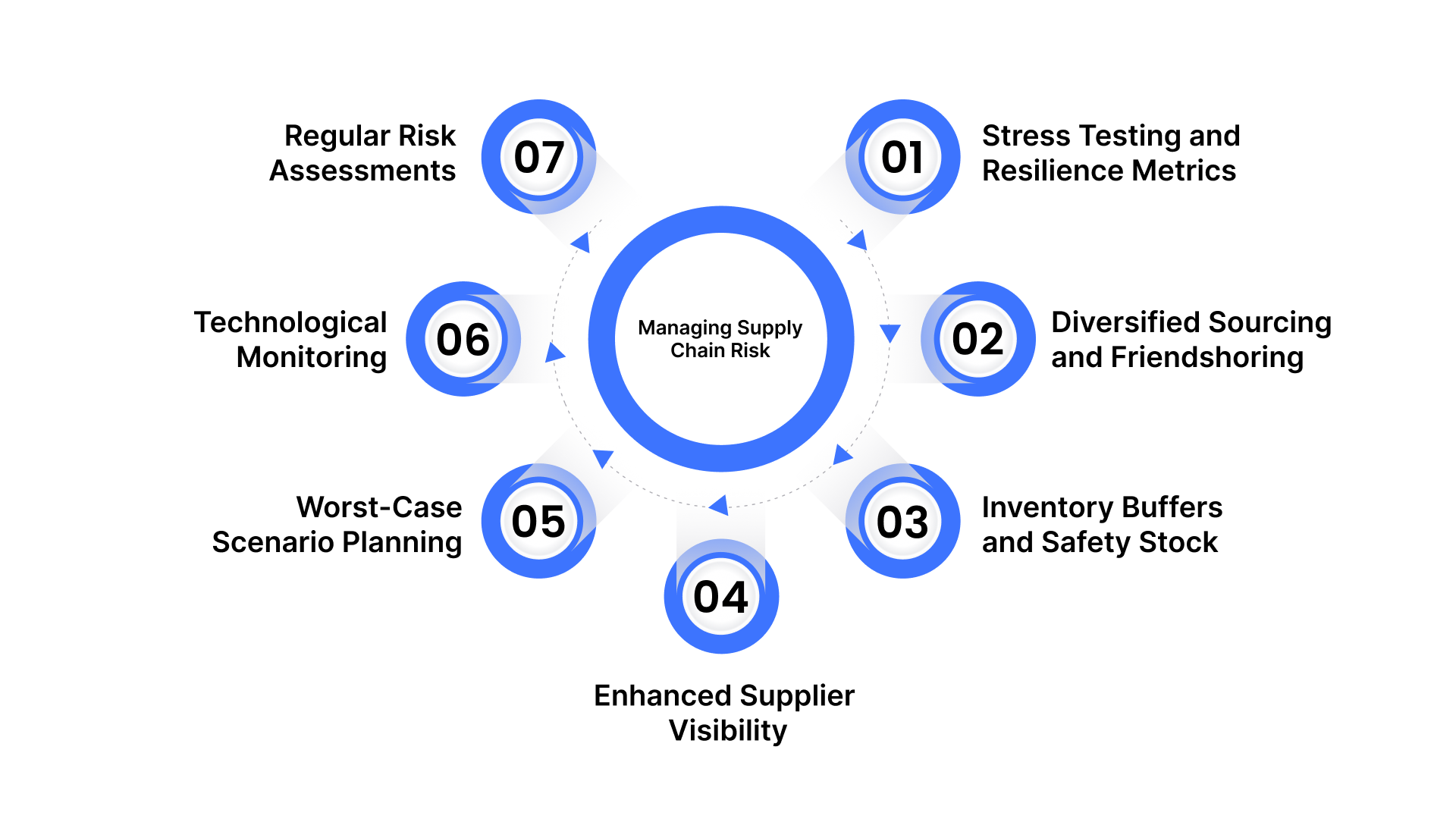

Proven Strategies for Managing Supply Chain Risk

Effectively managing supply chain risk is about anticipating, measuring, and mitigating disruptions rather than attempting to eliminate them entirely. Companies that combine analytical methods with targeted strategies can maintain operational continuity and minimize financial impact.

Stress Testing and Resilience Metrics

Measuring Time to Recover (TTR) and Time to Survive (TTS), concepts developed by MIT professor David Simchi-Levi, allows organizations to quantify how quickly a supply chain node can regain capacity and how long it can sustain operations after a disruption. These metrics guide inventory planning, contingency measures, and financial impact assessments, making risk decisions data-driven rather than reactive.

Diversified Sourcing and Friendshoring

Relying on a single region or supplier concentrates risk. Shifting supply to multiple locations, including nearshore or allied “friendshoring” partners, reduces exposure to geopolitical instability, shortens transit times, and improves responsiveness to sudden market changes. A +1 supplier strategy ensures resilience while avoiding unnecessary cost increases.

Inventory Buffers and Safety Stock

Maintaining a well-calculated buffer stock safeguards against sudden demand surges and supplier delays. Predictive demand models and analytics tools help companies determine the right level of inventory to align with real-time market conditions without tying up excessive capital.

Enhanced Supplier Visibility

Understanding all tiers of the supply chain allows early identification of vulnerabilities. Greater transparency in supplier operations enables informed decision-making and proactive mitigation before disruptions propagate downstream.

Worst-Case Scenario Planning

Modeling extreme events, from natural disasters to supplier insolvency, helps create actionable business continuity plans. Organizations prepared for worst-case scenarios can respond quickly and effectively, minimizing operational downtime and financial losses.

Technological Monitoring and AI Insights

AI-driven analytics and procurement monitoring tools provide real-time intelligence, identifying emerging risks before they escalate. Continuous assessment across internal and third-party data ensures supply chain teams are always acting on verified, current information.

Must read: How to Conduct a Comprehensive Security Risk Assessment?

Regular Risk Assessments and Training

Ongoing supplier evaluations and internal risk awareness programs ensure teams recognize early warning signs and understand their roles in mitigating threats. Continuous training keeps risk management embedded in daily operations and strengthens organizational resilience.

Even with these strategies, monitoring vendor networks in real time is challenging. Auditive centralizes continuous risk oversight, tracking supplier performance, control changes, and trust indicators, turning these strategies into actionable, ongoing risk monitoring across the entire supply chain ecosystem.

How Auditive Strengthens Supply Chain Risk Oversight

Financial and operational losses can result from a single supplier disruption. Auditive provides real-time visibility into vendor risk, transforming strategy into actionable monitoring.

Continuous Vendor Monitoring: Tracks changes in certifications, controls, and incidents across the vendor lifecycle, surfacing risks immediately.

Centralized Trust Profiles: Vendors maintain live profiles with verified controls and evidence, eliminating fragmented documents and emails.

Network-Wide Risk Insights: Reveals sub-tier dependencies and hidden vulnerabilities that traditional audits miss.

Predictive Analytics: AI highlights anomalies and emerging risks, enabling proactive mitigation.

Seamless Integrations: Connects with procurement and vendor management systems to ensure risk signals flow into daily operations.

Why it matters: Auditive converts supply chain risk strategies into ongoing, signal-driven oversight, giving teams continuous insight into suppliers and sub-tier vendors without relying on periodic reviews.

Summary

Effective supply chain risk management goes beyond strategy; it relies on continuous vendor risk management to detect and address issues before they disrupt operations. Diversifying suppliers, maintaining inventory buffers, and modeling scenarios reduce exposure, but real-time visibility into vendor performance and sub-tier dependencies is what ensures operational continuity.

Platforms like Auditive provide a centralized Trust Center that tracks vendor controls, certifications, and incidents, giving teams signal-driven visibility across the entire supply network. By integrating ongoing monitoring with strategic planning, organizations can safeguard operations, maintain supply continuity, and reduce financial and operational impact.

Schedule a demo with Auditive today to see how continuous vendor oversight can protect your operations.

FAQs

1. What is supply chain risk management?

It’s the process of identifying, assessing, and mitigating potential disruptions across suppliers and logistics networks to maintain operational continuity.

2. How does Auditive support supply chain risk management?

Auditive provides continuous vendor monitoring, centralized Trust Profiles, and AI-driven insights that reveal emerging risks and sub-tier vulnerabilities.

3. What is the benefit of nearshoring or “friendshoring”?

Sourcing from nearby or allied countries reduces reliance on high-risk regions, shortens transit times, and enhances responsiveness during disruptions.

4. How can organizations quantify supply chain disruptions?

Metrics like Time to Recover (TTR) and Time to Survive (TTS) measure how long a supply chain node takes to regain capacity and how long operations can continue during disruption.

5. Why is ongoing monitoring better than periodic audits?

Continuous monitoring provides real-time signals, enabling teams to act immediately on vendor changes and risks, rather than reacting after incidents occur.