Supplier Information Validation Methods You Need to Know

Supplier information validation is an essential process that helps organizations evaluate and verify their suppliers before entering into any partnership. Supplier company information validation methods allow businesses to identify and mitigate risks, ensure quality, and maintain compliance, ultimately securing their supply chain and safeguarding their reputation.

If you are validating suppliers for the first time or looking to improve existing processes, the right validation methods will help you make informed decisions that protect your organization.

This article will look into the importance of supplier validation, the methods used in the validation process, and best practices to implement in your business.

Key Takeaways

Supplier information validation ensures that vendors meet necessary standards, reducing operational, compliance, and financial risks.

A comprehensive supplier validation process includes reviewing documents, assessing capabilities, and conducting due diligence.

Continuous monitoring of supplier performance and compliance is vital to ensure long-term business stability.

Supplier validation minimizes the risk of legal, financial, and reputational issues by ensuring vendors meet your company’s requirements.

Using structured validation methods can help businesses establish long-term, trustworthy partnerships with reliable suppliers.

What is Supplier Validation?

Supplier validation is the process of evaluating and verifying the information and capabilities of potential or current suppliers. It ensures that suppliers meet specific criteria such as quality standards, financial stability, legal compliance, and operational capacity before forming a business relationship.

This process typically includes reviewing various types of documentation, conducting assessments, and performing audits to ensure that suppliers are capable of meeting the expectations and requirements of the business.

Vendor Risk Management provided by Auditive allows you to evaluate potential risks across your entire supply chain in real time. With continuous monitoring, you can identify and mitigate threats quickly, ensuring your vendors meet security and compliance standards without delay. Stay ahead of risks and protect your business with Auditive’s automated risk assessments.

Once you understand the concept of supplier validation, it’s important to know how the information validation process works in practice.

Why is supplier validation important?

Supplier validation is a crucial process for mitigating risks, ensuring quality assurance, and maintaining compliance with industry standards. Proper validation can lead to better supplier relationships, cost efficiencies, and long-term partnerships.

Risk mitigation: Supplier validation helps mitigate various risks, including supply chain disruptions, non-compliance with regulations, and potential financial instability. It ensures that suppliers meet your company’s risk standards, reducing the chances of operational setbacks.

Quality assurance: Validating suppliers helps ensure that they maintain high-quality products and services, which is essential for meeting customer expectations and maintaining the business’s reputation. This can include checking product quality, quality control systems, and compliance with industry standards.

Cost efficiency: Supplier validation ensures that businesses are engaging with suppliers that can offer competitive pricing without compromising quality. This can lead to better pricing agreements and long-term cost savings.

Regulatory compliance: Ensuring that suppliers comply with all relevant regulatory standards is vital for avoiding penalties and legal issues. Supplier validation ensures that all parties involved in the supply chain adhere to industry-specific regulations.

Long-term partnerships: Establishing validated suppliers builds stronger, more transparent relationships, leading to long-term partnerships that are beneficial for both parties. This reduces the time and cost associated with switching suppliers.

Also Read: Mastering Supplier Risk Management Strategies

The next step is to understand the specific steps involved in supplier information validation, which ensures you are evaluating vendors properly.

Supplier Information Validation Process

The supplier validation process involves multiple steps designed to ensure that vendors meet the required standards and can deliver reliably. The following process is commonly used to validate supplier information:

1. Initial screening

The validation process begins with gathering basic information about potential suppliers. This includes reviewing the company profile, certifications, and references. At this stage, you assess whether the supplier meets your minimum requirements, such as industry experience, location, and basic compliance with regulations.

2. Documentation review

At this stage, businesses request and review key documents provided by the supplier. These include:

Business licenses and registrations: Verifies the supplier’s legal status and ability to operate.

Quality certifications: Documents such as ISO 9001 or industry-specific certifications confirm the supplier’s commitment to quality standards.

Financial statements: Assessing financial documents helps ensure the supplier’s financial stability and capability to meet obligations.

Insurance policies: Ensures the supplier has the necessary insurance to protect against unforeseen circumstances.

Compliance certificates: Verifies adherence to regulations such as environmental standards, labor laws, or safety standards.

This review ensures that the supplier is legally and operationally sound, fulfilling the minimum operational and regulatory requirements.

3. Capability assessment

A thorough evaluation of the supplier’s capabilities is conducted to determine if they can meet your specific needs. This assessment typically includes:

Production capacity: Can the supplier scale to meet your demand?

Technical expertise: Does the supplier have the technical know-how to meet your specifications?

Quality management systems: Does the supplier have processes in place to maintain consistent quality?

Infrastructure and equipment: Is the supplier’s infrastructure adequate for meeting your needs?

Workforce skills: Does the supplier employ skilled professionals who can effectively meet the required standards?

The capability assessment ensures that the supplier has the infrastructure and skills necessary to fulfill your business requirements.

4. Due diligence

Due diligence involves a deeper investigation into the supplier’s financial stability, legal compliance, and reputation in the market. Common methods for due diligence include:

Financial audits: Reviewing financial records to verify the supplier’s ability to fulfill long-term contracts.

Background checks: Analyzing the history of the supplier’s management, business performance, and legal standing.

Reference checks: Reaching out to the supplier’s past clients to assess their reliability and service quality.

Past performance analysis: Reviewing the supplier’s previous contracts and their ability to meet deadlines, budgets, and quality standards.

This step helps identify any potential risks related to the supplier’s ability to meet expectations.

5. On-site audit

For critical suppliers, an on-site audit may be necessary. This involves visiting the supplier’s facilities to inspect their operations, processes, and quality control systems. During this audit, key areas to evaluate include:

Manufacturing processes: Are they efficient and do they meet the required standards?

Safety and environmental standards: Is the supplier following necessary safety protocols and environmental regulations?

Employee working conditions: Are employees treated ethically and working under safe conditions?

Inventory management: Is the supplier’s inventory management system robust enough to prevent disruptions?

An on-site audit offers a first-hand look at the supplier’s operations and provides insights that may not be evident through documentation alone.

Also Read: Best Practices for an Efficient Supplier Onboarding Process

6. Risk assessment

At this stage, the potential risks associated with the supplier are assessed. This includes evaluating:

Supply chain disruptions: Can the supplier handle disruptions, such as political unrest or natural disasters, without affecting your business?

Geographic or political risks: Does the supplier’s location introduce any risk factors, such as political instability?

Financial instability: Does the supplier show signs of financial trouble that could jeopardize your relationship?

Non-compliance with regulations: Are there any concerns regarding the supplier’s adherence to local or international laws?

Using a risk matrix can help prioritize these risks and create a plan to mitigate them effectively.

7. Performance evaluation

Before finalizing the supplier, it’s essential to evaluate their performance based on key metrics, such as:

Quality of products or services: Does the supplier meet your required quality standards consistently?

On-time delivery rates: How reliable is the supplier in meeting delivery deadlines?

Cost competitiveness: Does the supplier offer competitive pricing without sacrificing quality?

Communication and responsiveness: How well does the supplier communicate and address issues in a timely manner?

Innovation and flexibility: Can the supplier adapt to changing needs or technological advancements?

Evaluating these metrics helps ensure that the supplier will be a reliable partner in the long term.

8. Final decision

After completing all assessments, the final decision is made based on the comprehensive evaluation of the supplier’s abilities, risks, and performance metrics. A vendor validation checklist should be used at this stage to ensure that every critical aspect of the supplier’s qualifications has been considered.

With Auditive’s Trust Center, you can create a transparent, secure environment for your vendor relationships. By enabling vendors to showcase their security practices and certifications, you can confidently assess and validate their compliance. This collaborative network helps buyers and sellers align on expectations, reducing risk and improving trust across the board.

To simplify this process, a detailed vendor validation checklist will help you ensure all necessary information is collected and assessed.

Vendor Validation Checklist

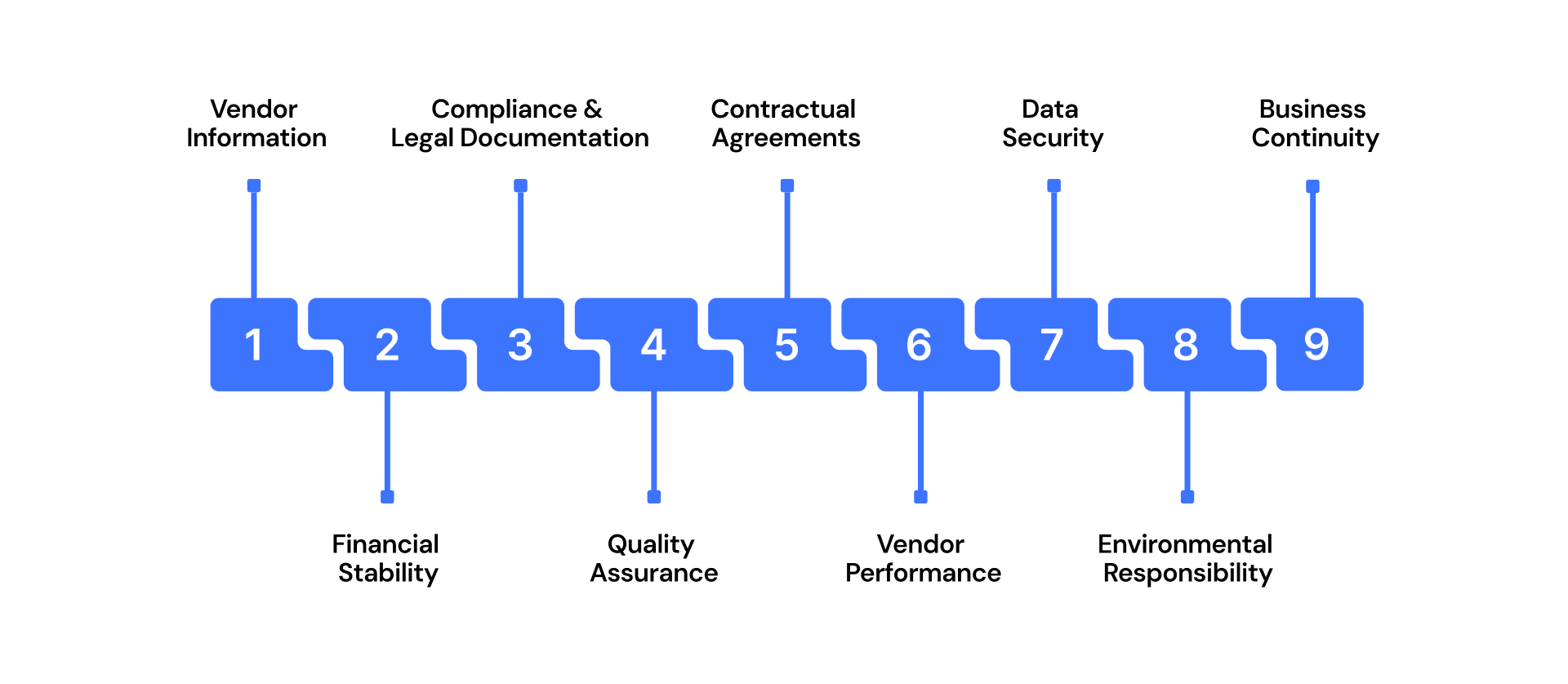

A detailed vendor validation checklist is essential to ensure that all critical factors are considered when assessing potential suppliers. This checklist covers vital aspects, such as vendor information, financial stability, and compliance.

Vendor information: Gather key details like the business name, legal business name, contact information, registration numbers, and ownership structure. These help establish the legitimacy and identity of the supplier.

Financial stability: Assess the supplier’s financial health by reviewing their audited financial statements, credit reports, and insurance coverage. This ensures they can meet their obligations and manage potential risks.

Compliance and legal documentation: Verify the supplier’s compliance with relevant laws and industry standards by reviewing business licenses, ISO certifications, and anti-corruption policies. This confirms their legal and operational integrity.

Quality assurance: Ensure that the supplier adheres to high-quality standards by reviewing quality control processes, product specifications, and third-party audits. This guarantees that they can meet your quality requirements.

Contractual agreements: Examine the vendor’s contracts, including payment terms, termination clauses, and remedies for breach. This helps protect your business by outlining clear expectations and legal safeguards.

Vendor Performance: Collect references, case studies, and reviews from the supplier’s previous or current clients. This provides insight into their reliability, past performance, and potential for future success.

Data security: Assess the supplier’s cybersecurity measures, including confidentiality agreements and compliance with data protection laws. This ensures that sensitive business data is safeguarded from potential threats.

Environmental responsibility: Review the supplier’s environmental management policies, certifications, and sustainability goals. This demonstrates their commitment to corporate social responsibility and minimizes environmental risks.

Business continuity: Verify the supplier’s business continuity and disaster recovery plans, insurance coverage, and redundancy measures. This ensures that they can continue to operate in the event of disruptions or emergencies.

Also Read: Effective Strategies for Overcoming Supplier Onboarding Challenges

If supplier validation is neglected, it can lead to various risks. Now, let’s explore what those risks are and how they can impact your business.

5 Risks of Avoiding Vendor Validation

Failing to properly validate suppliers exposes your business to significant risks, which could lead to operational, financial, and reputational damage. Below are some of the key risks:

Operational risk: Unreliable suppliers may cause delays, quality issues, or disruptions, which can affect your production timelines, customer satisfaction, and overall operational efficiency.

Compliance risk: Suppliers who fail to meet regulatory requirements may face legal penalties, fines, or a loss of business licenses, leading to costly repercussions for your organization.

Financial risk: If a supplier faces financial instability, it may fail to meet their obligations, affecting your supply chain. This can lead to financial losses and operational disruption.

Reputational risk: Working with non-compliant or unreliable suppliers can harm your company’s reputation. Negative publicity or customer dissatisfaction can damage brand trust and customer loyalty.

Credibility risk: If a supplier fails to meet agreed-upon terms or quality standards, it can impact your business’s credibility with clients, partners, and stakeholders, leading to potential loss of future contracts.

Real-time risk monitoring by Auditive provides ongoing surveillance of your vendor’s risk profile at scale. While it doesn’t track vendor performance, it ensures that any security vulnerabilities are promptly identified and addressed. Auditive’s continuous monitoring allows you to make informed decisions and reduce exposure to potential risks in your third-party relationships.

To avoid these risks, implementing best practices for supplier validation is key to ensuring reliable and compliant partnerships.

5 Best Practices for Supplier Validation

To ensure effective supplier validation, consider implementing these best practices to mitigate risks and optimize your supplier relationships. These steps will help your business select reliable, compliant, and capable vendors.

Define your risk appetite: Establish clear criteria for supplier selection based on your company’s risk tolerance, operational requirements, and the nature of the relationship. This ensures that your vendor choices align with your overall risk management strategy.

Tier vendors based on risk: Prioritize high-risk suppliers for more detailed evaluation and frequent monitoring. By categorizing suppliers by risk level, you can allocate resources efficiently and address critical concerns proactively.

Customize risk questionnaires: Tailor your risk questionnaires to gather specific information from each supplier, including their compliance status, financial health, and operational capabilities. Customizing these questionnaires ensures you collect relevant and accurate data.

Monitor performance continuously: Continuous monitoring helps address problems before they escalate and ensures suppliers maintain high standards.

Conduct on-site audits: For critical suppliers, conduct regular on-site visits to evaluate their operations, manufacturing processes, and quality control systems. On-site audits provide valuable insights that can’t be obtained from documentation alone and help maintain transparency.

Also Read: Supplier Due Diligence for Managing Procurement Risk

With best practices in mind, utilizing tools like Auditive can streamline and automate supplier validation to further reduce errors and inefficiencies.

Streamline Supplier Information Validation with Auditive

Auditive simplifies supplier information validation by offering powerful tools that help businesses efficiently evaluate, monitor, and manage supplier risks at scale. With our advanced features, you can make informed decisions and maintain robust vendor relationships.

Vendor risk management: Quickly assess supplier risks in real-time, across your entire supply chain. Auditive’s risk management tool helps you identify and mitigate potential threats continuously, ensuring compliance and operational reliability.

Trust center: Utilize Auditive's Trust Center to gain a transparent view of your supplier’s security and compliance practices. This buyer-seller network allows both parties to evaluate and showcase certifications, improving trust and collaboration.

Continuous monitoring: Stay ahead of risks with continuous monitoring and automated alerts, ensuring that your suppliers remain compliant and meet your quality and security standards over time.

Comprehensive supplier evaluation: Automate the entire supplier validation process with Auditive, from initial screening to ongoing assessments, saving time and reducing manual effort.

With Auditive’s cutting-edge solutions, you can streamline your supplier validation process, minimize risks, and build stronger, more reliable supplier relationships.

Final Thoughts

Supplier information validation is a critical process for ensuring that your vendors meet your company’s standards and reduce operational, financial, and compliance risks. By following effective supplier company information validation methods, businesses can streamline the supplier validation process, mitigate risks, and establish long-term, reliable partnerships.

Whether it's through documentation review, on-site audits, or risk assessments, supplier validation ensures that you’re working with vendors who align with your strategic goals.

Managing vendor risk has never been easier with Auditive’s Vendor Risk Management platform. It helps you assess vendors' security practices through verified profiles, ensuring your business is protected against third-party risks. With Auditive’s AI-powered verification and monitoring, you can confidently manage your vendor relationships and maintain a secure business environment.

Reach out to Auditive to make sure your supply chain is secure, compliant, and of high quality.

FAQs

1. What is supplier information validation?

Supplier information validation ensures that a vendor meets your company's requirements, verifying details like compliance, financial stability, and quality to reduce risks.

2. Why is supplier validation crucial?

Supplier validation reduces operational, financial, and compliance risks, ensuring that vendors are reliable, secure, and able to meet the required quality standards.

3. What documents are typically reviewed in supplier validation?

Common documents include business licenses, certifications, financial statements, compliance certificates, and insurance policies, verifying a supplier’s legal standing and operational soundness.

4. How often should supplier validation be conducted?

Supplier validation should be conducted before onboarding, during the relationship, and periodically reassessed to ensure continued compliance and mitigate growing risks.

5. What are the consequences of skipping supplier validation?

Skipping validation can lead to operational disruptions, legal penalties, financial instability, and reputational damage, making it crucial for maintaining secure business operations.